to deterioration and structural failure of the concrete.

Alkalis, acids, and sulfates in the water tend to react with

the chemicals in the cement. The result is inadequate

cementing and weakened concrete. Water must be free

of these chemicals to be used in concrete mixing.

SEAWATER.— The salts in seawater are normally

thought of as being corrosive; however, seawater is used

sometimes in concrete mixing with satisfactory results.

A loss of 10 to 20 percent in compressive strength can

be expected when the same amount of seawater as fresh

water is used. That can be compensated somewhat by

reducing the water-cement ratio.

Aggregates

The aggregates normally used for concrete are

natural deposits of sand and gravel, where available. In

some localities, the deposits are hard to obtain and large

rocks must be crushed to form the aggregate. Crushed

aggregate usually costs more to produce and will require

more cement paste because of its shape. More care must

be used in handling crushed aggregate to prevent poor

mixtures and improper dispersion of the sizes through

the finished concrete. At times, artificial aggregates,

such as blast-furnace slag or specially burned clay, are

used.

TYPES OF AGGREGATE.— Aggregates are

divided into two types as follows:

. FINE AGGREGATE. “Fine aggregate” is

defined as material that will pass a No. 4 sieve and will,

for the most part, be retained on a No. 200 sieve. For

increased workability and for economy as reflected by

use of less cement, the fine aggregate should have a

rounded shape. The purpose of the fine aggregate is to

fill the voids in the coarse aggregate and to act as a

workability agent.

. COARSE AGGREGATE. Coarse aggregate is a

material that will pass the 3-inch screen and will be

retained on the No. 4 sieve. As with fine aggregate, for

increased workability and economy as reflected by the

use of less cement, the coarse aggregate should have a

rounded shape. Even though the definition seems to

limit the size of coarse aggregate, other considerations

must be accounted for.

When properly proportioned and mixed with

cement, these two groups yield an almost voidless stone

that is strong and durable. In strength and durability,

aggregate must be equal to or better than the hardened

cement to withstand the designed loads and the effects

of weathering.

It can be readily seen that the coarser the aggregate,

the more economical the mix. Larger pieces offer less

surface area of the particles than an equivalent volume

of small pieces. Use of the largest permissible maximum

size of coarse aggregate permits a reduction in cement

and water requirements.

One restriction usually assigned to coarse aggregate

is its maximum size. Larger pieces can interlock and

form arches or obstructions within a concrete form. That

allows the area below to become a void, or at best, to

become filled with finer particles of sand and cement

only. That results in either a weakened area or a

cement-sand concentration that does not leave the

proper proportion to coat the rest of the aggregate. The

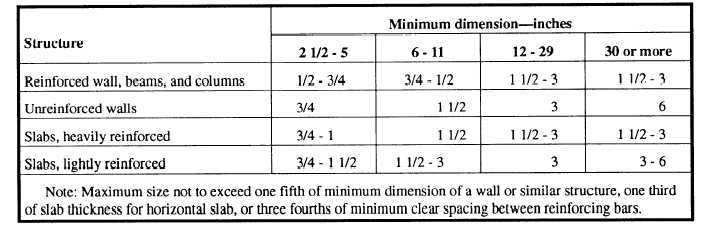

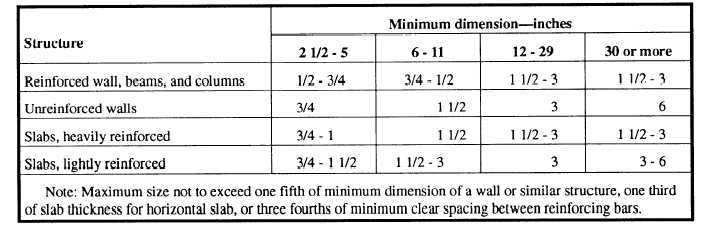

maximum size of coarse aggregate must be no larger

than the sizes given in table 13-1. The capacity of the

mixing equipment may also limit the maximum

aggregate size.

GRADATION.— Gradation of aggregate refers to

the amount of each size of particle used in the mix. Too

large a proportion of coarse aggregate leaves voids that

require more cement paste to fill. That affects the

Table 13-1.—Maximum Recommended Size of Coarse Aggregate

13-21