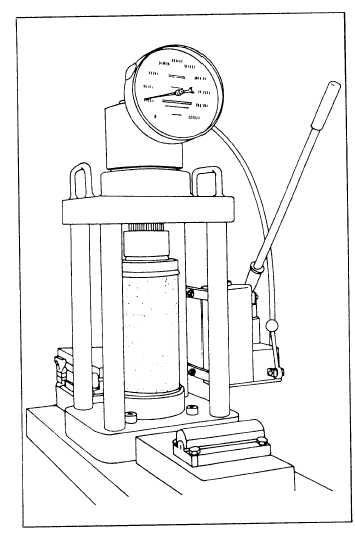

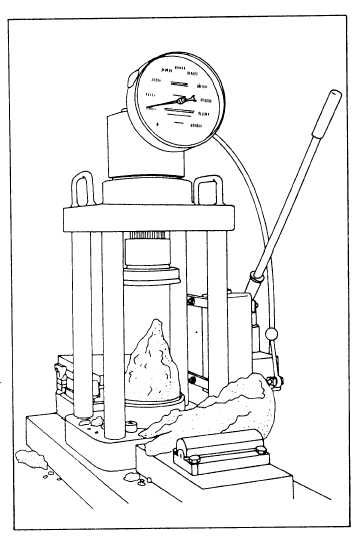

Figure 13-22.—Compression-testing machine.

the spherical seat. Check the operation of the machine.

Keep the previously prepared test specimen moist by

covering it with wet burlap during the period between

removing the specimen from the curing environment

and testing. That applies to each specimen you will test.

2. Determine the diameter of the test specimen to

the nearest 0.01 inch by averaging two diameters

measured at right angles to each other at midheight of

the cylinder. Measure the length, including caps, to the

nearest 0.1 inch. Record the dimensions on a prepared

data sheet.

3. Place the specimen on the lower bearing block,

bring the upper block almost to contact, and align the

axis of the specimen with the center of thrust of the

spherical head. Carefully and slowly bring the spherical

head into contact with the specimen, rotating the

movable portion gently by hand so that uniform seating

is obtained. Apply the test load continuously and

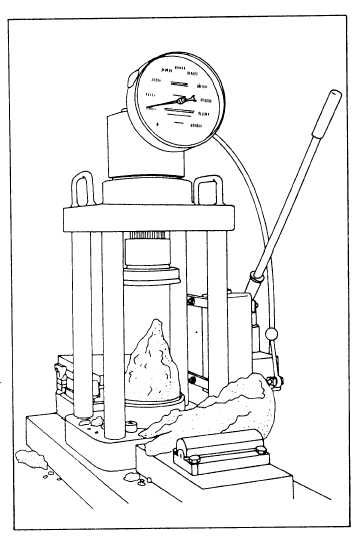

Figure 13-23.—Normal fracture of concrete test cylinder in

compression.

without shock at a rate of 20 to 50 pounds per square

inch (psi). Observe and record the maximum load during

the test. Observe the type of fracture and record any

unusual features. The normal cone type of fracture is

illustrated in figure 13-23.

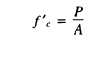

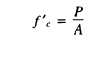

4. Calculate the compressive strength of the

concrete using the following formula:

Where:

f´c =

P =

A =

compressive strength (in psi)

maximum load (in pounds)

cross-sectional area of specimen (in

inches)

13-31