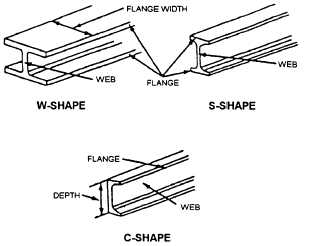

Figure 1-32.—Structural steel shapes and designations.

terminology applied to structural steel members, the use

of these members, and the methods by which they are

connected.

STRUCTURAL STEEL SHAPES

Structural steel is manufactured in a wide variety of

cross-sectional shapes and sizes. Figure 1-32 shows

many of these various shapes.

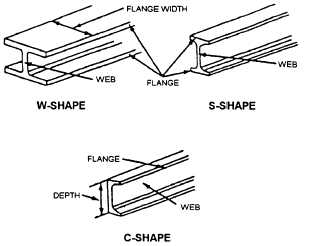

Figure 1-33 shows cross-sectional views of the

W-shape (wide flange), the S-shape (American

Standard I-beam), and the C-shape (American Standard

channel). The W-shape is the most widely used

structural member for beams, columns, and other

load-bearing applications. As seen in the figure, it has

parallel inner and outer flange surfaces that are of

constant thickness. This flange design provides greater

cross-sectional area in the flanges, which results in

greater strength than is provided by the S-shape, which

has a slope of approximately 17 degrees on the inner

flange surfaces. The C-shape is similar to the S-shape in

that its inner flange surface is also sloped approximately

17 degrees. The C-shape is especially useful in locations

section describes structural steel shapes, the

Figure 1-33.—Structural shapes.

where a single flat surface on one side is required. When

used alone, the C-shape is not very efficient as a beam

or column. However, efficient built-up members maybe

constructed of charnels assembled together with other

structural shapes and connected by rivets or welds.

The W-, S-, and C-shape structural members are

designated by their nominal depth, in inches, along the

1-17