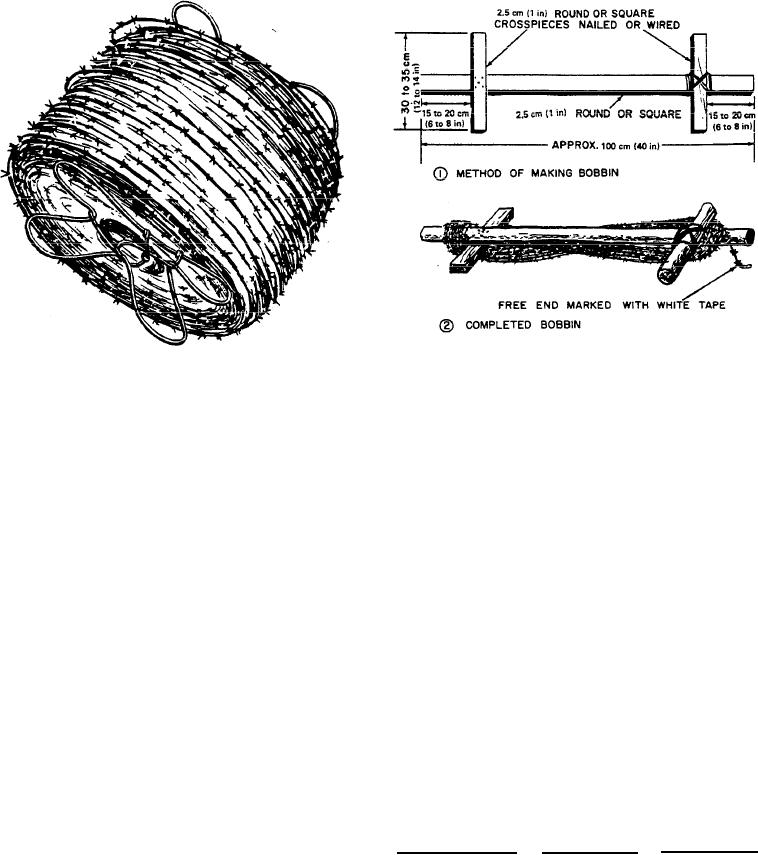

Figure 8-6.--Barbed-wire bobbin.

Figure 8-5.--Barbed-wire reel.

4. Wind the wire in a figure-eight shape on the

bobbin sticks.

Handling

5. Tie a piece of white tracing tape to the loose end

of the wire to facilitate finding it.

When handling barbed wire, wear the standard

barbed-wire gauntlets shown in figure 8-4 or heavy

BARBED-STEEL TAPE

leather gloves. They permit faster work and protect

against cuts and scratches. As an added safety

The physical characteristics of barbed-steel tape

precaution, grasp the wire with your palms down.

(fig. 8-7) are as follows:

Width: 3/4 inch

Issue

Thickness: 0.022 inch "

Barbed wire is issued in reels (fig. 8-5), containing

Weight: 4,438 pounds/164 feet

about 1,312 feet of wire. The wire weighs 90 pounds and

the reel about 1.3 pounds. When a fence is being built,

Width of barb: 7/16 inch

two men carry one reel.

Interval between barbs: 1/2 inch

Breaking load: 500 pounds

Bobbins

Two significant characteristics listed above that are

Bobbins (fig. 8-6) holding about 98 feet of wire are

important to field users are the weight and the breaking

prepared, normally in rear areas, for use in building short

load. A comparison of pertinent characteristics of barbed

lengths of fence and in repairing entanglements. When

tape and barbed wire is shown below.

bobbins are used, two men handle one bobbin. One

BARBED WIRE

BARBED TAPE

CHARACTERISTIC

unwinds the bobbin and the other installs the wire. Two

or more men can make the bobbins by following these

104.5 pounds

Weight (1,312 feet)

35.5 pounds

steps:

1,075.0 pounds

270.0 pounds

Breaking load

1. Prepare the bobbin sticks.

4 inches

1/2 inch

Barbed interval

2. Rig the reel on an improvised trestle or other

23 inches

Size (9,900 feet)

18 5/8 x 19 1/2

Support.

x 17112 inches

3. Have one man unroll and cut 98-foot lengths of

2

2

9.7 feet

3.6 feet

cube

wire, fastening one end of each to the trestle.

8-4