with the hollow surface (concave side) facing the

enemy, so friendly small-arms fire will not ricochet

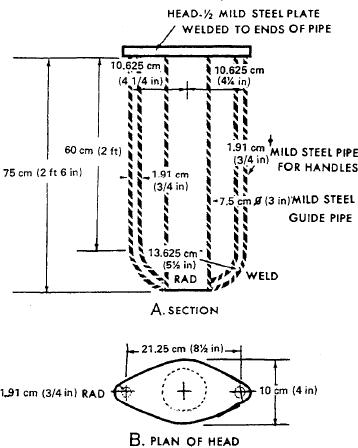

back toward your position. An expedient picket

driver, which can be fabricated locally, is shown in

figure 8-11. Constructed as shown, it weighs

approximately 5 1/2 pounds and is operated by two

men. One man holds the picket in a vertical position,

and the other slides the driver over the picket and

drives it into the ground. Then both men work the

picket driver up and down until the required depth is

reached. Drive short pickets by turning the picket

driver upside down and using the head as a hammer.

Use the bucket of a front-end loader to push U-shaped

pickets into the ground when the tactical situation

permits the use of equipment.

In locations where frozen ground prevents driving

of the U-shaped pickets, use an Arctic adapter. The

adapter is made of steel and consists of a baseplate

equipped with an adjustable channel receptacle and

two anchor pins. Anchor it by driving the anchor pins

through holes in the baseplate into the ground. One

anchor-pin drive sleeve with a driving pin is provided

with each 20 adapters to aid anchor pin emplacement.

When adapters are not available, start a hole with a

Figure 8-11.-Expedient picket driver.

picket. The picket can be frozen in place by pouring

water and snow into the hole.

picket inserted in the bottom eye of the picket for

leverage. Use the bottom eye in order to avoid twisting

WOODEN PICKETS

the picket. Install screw pickets so the eye is to the right

of the picket, as seen from the friendly side, and standard

You can use expedient wooden pickets of several

ties can be made easily. Screw pickets tend to be less

types.

rigid than other types but are desirable because you can

install them rapidly and silently. When silence is

Cut round poles 4 inches in diameter to standard

necessary, wrap the driftpin used in installing the pickets

picket lengths, sharpen them on one end, and drive them

with cloth.

with a maul. Use the pickets without peeling the bark to

prevent the wire from sliding on the picket and to

simplify camouflage. You need longer pickets in loose

U-shaped Pickets

or sandy soil and when driving through a snow cover.

Driving wooden pickets is not as noisy as driving steel

The U-shaped picket is a cold-formed steel picket

pickets, and you can reduce the noise further by

with a U-shaped cross section, pointed at one end for

fastening a section of tire tread over the face of the

driving. It is notched for wire ties and the pointed end has

hammer or maul. For driving in hard earth, wrap the

a punched hole for wires used in bundling the pickets.

picket tops with wire to avoid splitting. Hardwood

Drive the U-shaped pickets with a sledgehammer. Use

pickets, properly installed, are sturdy and rigid.

a stake driving cap on the tip of the picket to prevent

You can use dimensional lumber that is ripped to a

the sledge from deforming it. Driving the pickets is

square cross section instead of round poles. This is

noisier than installing screw pickets. However, you can

equally satisfactory except that it is more difficult to

reduce the noise by placing a piece of rubber tire over

camouflage. These pickets may be dipped in

the driving face of the sledge. The pickets are rigid and

camouflage paint before driving.

sturdy when installed properly. They are preferable to

screw pickets in situations where noise is not a

Standing trees and stumps may be used as pickets

disadvantage and time is available. Drive the pickets

when their location permits.

8-7