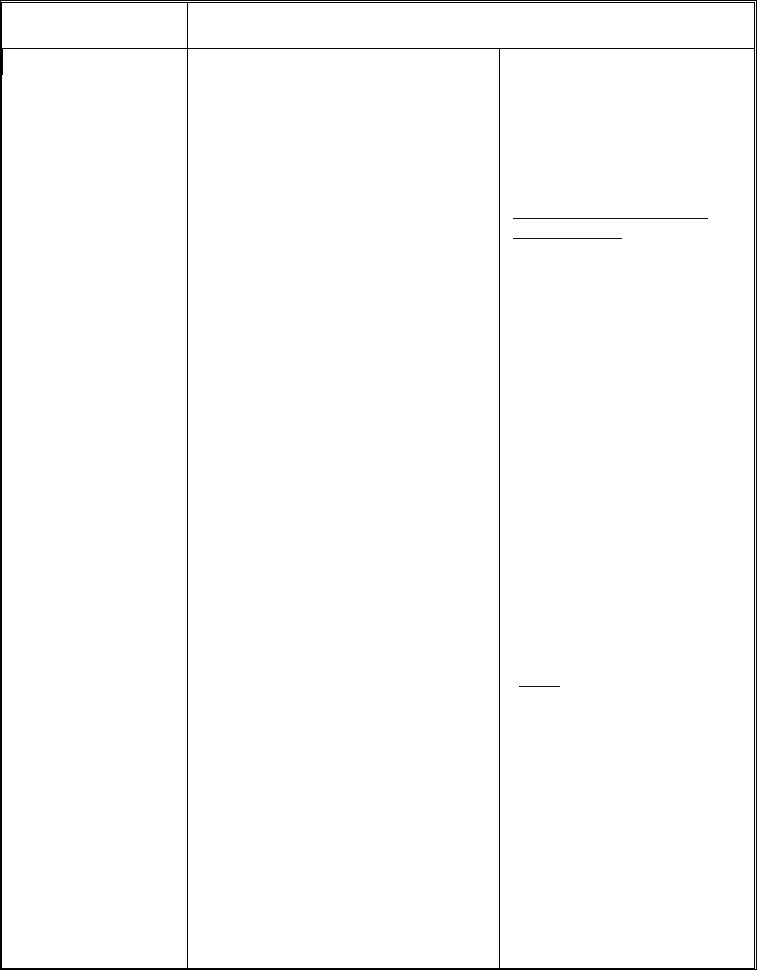

Table 13-1. Examples of the Use of Props to Support Training Drills/Scenarios (continued)

TYPE OF SIMULATED

EQUIPMENT AND PROPS

REMARKS

TRAINING

THAT CAN BE USED

Jammed WTD/WTH

Large masking tape X on the fitting; DCCT

Sparking: Use welder's sparking

member hold fitting handle to prevent

tool or strobe light

opening

Explosion: Bang on deck plates, the

more noise, the better the drills.

Hot Surface

Bubble wrap on fitting, deck, or bulkhead or

piece of charred wood

REPAIR PARTY ACTION

should include:

Bulkhead/Deck

Size of hole cut from black sheet rubber and

Charge fire hoses for all drills.

placed in position

Secure hose at the plug. To provide

Gas Free Test

Grease pencil marks on 4 gas analyzer,

realistic hose handling training

explosive meter or O2 indicator and

depending on drill scenario

Draeger tubes.

objectives.

No charged fire hose should be

Electrical Isolation

Actual isolation and hang SECURED signs

allowed into an electronics space

after watch stander places hands on correct

for training purposes.

component

Conduct actual shoring and pipe

patching.

OBA Activation

Fire-fighter member takes actual canister to

scene. A DCTT member takes canister and

Rig P-100--fire fighting or

replaces it with sticker or masking tape with

dewatering.

date written on it

Light off OBAs as practical,

AFFF Activation

Post-ACTIVATED sign on control switch

considering allowance

after the watch stander attempts to push it

requirements.

(Ensure station is in RECIRC)

(Never use training canisters in a

drill scenario.)

Use of AFFF (Installed

Grease pencil marks on sight glass. Run

systems)

magnet down sight glass

Halon Effective

Hang white or gray streamers from

overhead near view ports. Cool boundaries

in surrounding spaces. White or gray

streamers near main space ventilation

outlets and stack

Halon Ineffective

Hang black streamers from overhead near

view ports. Hot boundaries (bubble wrap).

Black streamers near main space ventilation

outlets and stack

13-7