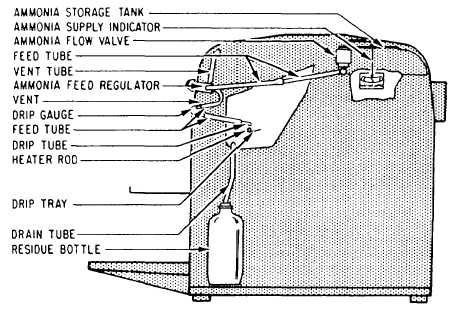

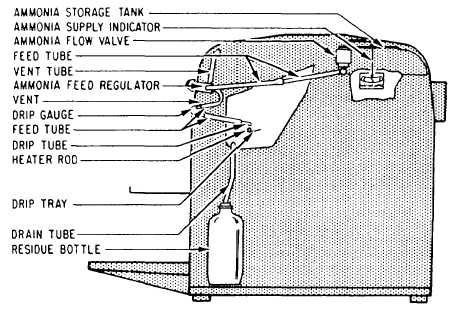

Figure 3-64.-Ammonia flow system.

tank through a gravity-feed system (fig. 3-64).

This feed system permits a smooth, even flow of

ammonia, thus minimizing the possibility of air

or vapor locking of the feed tubing. The amount

of ammonia fed into the developer is controlled

by a feed regulator at a rate of approximately 50

to 60 drops per minute. The ammonia is directed

into evaporating drip trays that are suspended in

the developer tank. Fastened to these trays are

electric heater rods. These rods, in conjunction

with a second thermo-switch controlled heater in

the developing tank, serve to heat the ammonia

and thereby accelerate the formation of ammonia

vapors. These vapors activate the image on the

print as they escape through the holes in the

upper part of the developer tank. Thus, a semi-

permanent image of those areas that were NOT

desensitized in the printing section is developed

on the print as it passes across the vapors.

To protect the machine from flooding with

ammonia when the machine is secured, an

automatic shutoff valve is located in the ammonia

feedline. This value shuts automatically when the

machine is secured and opens automatically when

the machine is turned on, thereby remitting

ammonia to the feed tray.

A second ammonia supply system being used

in some machines is called the anhydrous

ammonia system. Cylinders filled with anhydrous

ammonia supply the developing section with an

ammonia vapor. This vapor is directed into the

developer tank where it is distributed with the aid

of distilled water that is fed into the drip trays.

For safety reasons, cylinders should be stored

away from heat and sunlight. Do not allow the

temperature of the cylinders to reach a

temperature above 125°F. Position the cylinders

upright, and firmly attach them with a chain or

strap to a rigid supporting member, such as a wall.

Cylinders are attached to the developing tank

through a system of piping and fittings, When

changing a cylinder, close the valve on the

expended cylinder tightly by turning it clockwise.

Bleed off all pressure remaining in the feed line

by turning on the ammonia flow in the machine.

Disconnect the fitting or yoke cylinder connection.

Replace the cylinder and remove the protecting

valve cap. Ensure that a Teflon washer is in place.

Connect the fitting or yoke cylinder connection.

Make sure all connections are tight. Open the

cylinder valve. Check for possible leaks on all

connections by holding a piece of unexposed and

undeveloped diazo paper close to the connections.

If the diazo paper discolors, retighten the

connections.

A uniform flow of ammonia is maintained by

a pressure gauge located between the cylinder and

the developing section. In addition, the pressure

gauge indicates the amount of available ammonia

left in the cylinder. A new cylinder will have a

gauge reading of 150, while an empty cylinder will

indicate a reading of 50.

3-48