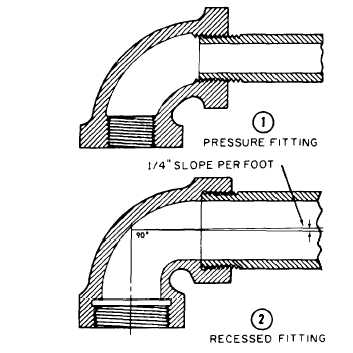

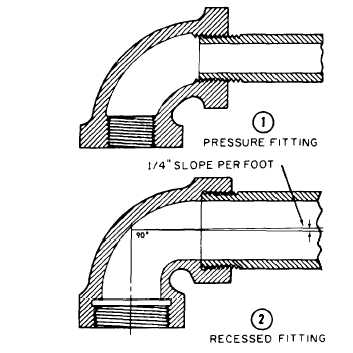

Figure 8-4.-Comparison of pressure and recessed (Durham)

types of fittings.

also be adapted to metal pipe fittings. The fittings

used on either steel pipe or wrought iron are

generally made of malleable iron or cast

iron. There are two types of iron pipe fittings

used: the PRESSURE type and the RECESSED

type (fig. 8-4).

The pressure type of fitting is the standard

fitting used on water pipe. The recessed type of

fitting, also known as a cast-iron drainage or

Durham fitting, is generally required on all

drainage lines. The recessed type is most suitable

for a smooth joint; it reduces the probability of

grease or foreign material remaining in the joint

and causing a stoppage in the line. Recessed

fittings are designed so that horizontal lines

entering them will have a slope of one-fourth in.

per foot.

ELBOWS (OR ELLS) 90° AND 45°.— These

fittings (fig. 8-5, close to middle of figure) are used

to change the direction of the pipe either 90 or

45 degrees. REGULAR elbows have female

threads at both outlets. STREET elbows change

the direction of a pipe in a close space where it

would be impossible or impractical to use an

elbow and nipple. Both 45- and 90-degree street

elbows are available with one female and one male

threaded end. The REDUCING elbow is similar

to the 90-degree elbow except that one opening

is smaller than the other.

TEES.— A tee is used for connecting pipes of

different diameters or for changing the direction

of pipe runs. A common type of pipe tee is the

STRAIGHT tee, which has a straight-through

portion and a 90-degree takeoff on one side. All

three openings of the straight tee are of the same

size. Another common type is the REDUCING

tee, similar to the straight tee just described,

except that one of the threaded openings is of a

different size than the other.

UNIONS.— There are two types of pipe

unions. The GROUND JOINT UNION consists

of three pieces, and the FLANGE UNION is

made in two parts. Both types are used for

joining two pipes together and are designed so that

they can be disconnected easily.

COUPLINGS.— The three common types of

couplings are straight coupling, reducer, and

eccentric reducer. The STRAIGHT COUPLING

is for joining two lengths of pipe in a straight run

that does not require additional fittings. A run

is that portion of a pipe or fitting continuing in

a straight line in the direction of flow. A

REDUCER is used to join two pipes of different

sizes. The ECCENTRIC REDUCER (also called

a BELL REDUCER) has two female (inside)

threads of different sizes with centers so designed

that when they are joined, the two pieces of pipe

will not be in line with each other, but they can

be installed so as to provide optimum drainage

of the line.

CAPS.— A pipe cap is a fitting with a female

(inside) thread. It is used like a plug, except that

the pipe cap screws on the male thread of a pipe

or nipple.

PLUGS.— Pipe plugs are fittings with male

(outside) threads. They are screwed into other

fittings to close openings. Pipe plugs have various

types of heads, such as square, slotted, and

hexagonal sockets.

NIPPLES.— A nipple is a short length of pipe

(12 in. or less) with a male thread on each end.

It is used for extension from a fitting.

At times, you may use the DIELECTRIC or

INSULATING TYPE of fittings. These fittings

connect underground tanks or hot-water tanks.

They are also used when pipes of dissimilar metals

8-4