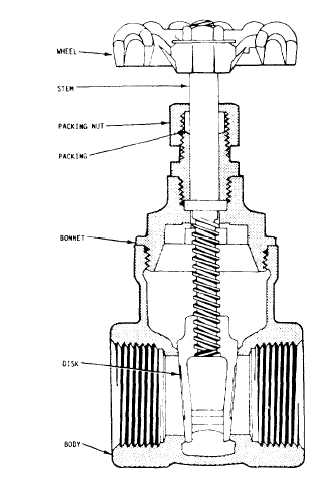

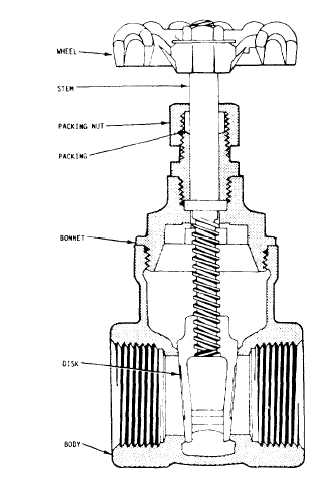

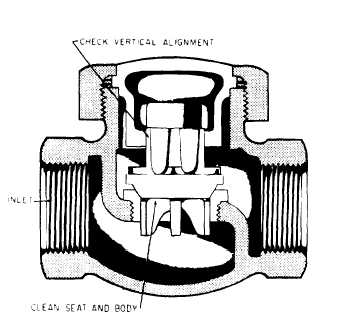

Figure 8-6.-Crow section of a gate valve.

GATE VALVE..— The gate valve (fig. 8-6) has

a wedge-shaped, movable plug, called a gate, that

fits tightly against the seat when the valve is

closed. When the gate is opened, an unrestricted

flow passage is provided. It allows fluid to flow

through in a straight line with little resistance and

less friction and pressure drop, provided the valve

gate or disk is kept fully opened. The gate valve

releases a variable amount with each turn of the

gate.

Gate valves must always be operated in

either their fully opened or fully closed posi-

tion,

never in any position to adjust the

rate of flow. A partly closed gate will cause

vibration and chattering, damaging the seating

surfaces.

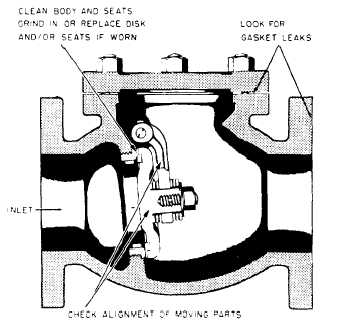

CHECK VALVE.— The check valve is used

principally to prevent backflow in pipelines

automatically. The valves are entirely automatic

and are used where flow of liquids, vapors, or

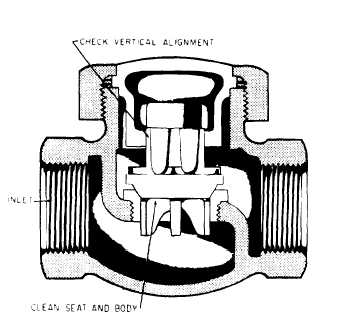

Figure 8-7.-Cross section of a swing check valve.

gases in one direction only is required. Check

valves fall into two main groups: swing check

valves and lift check valves. A SWING CHECK

VALVE, shown in figure 8-7, is used where an

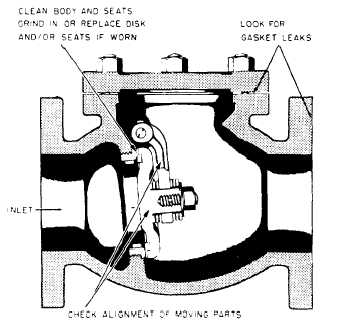

unrestricted flow is desired. A LIFT CHECK

VALVE is usually used for air or gases or

when operation of the check valve is frequent

(fig. 8-8).

8-7

Figure 8-8.-Lift check valve.