Sampling Procedures

Sampling (or obtaining) concrete for the

slump test should be accomplished accord-

ing to ASTM C 172. In this TRAMAN, only

the procedure of sampling from a revolving

drum truck mixer (TM) or agitator is discussed.

If you should ever need to sample from a paving

mixer, open-top truck mixer, or other type of

equipment, be sure to refer to the most recent

ASTM C 172.

Samples taken for the test specimens must

be representative of the entire batch. This

is accomplished by taking the samples at two

or more regularly spaced intervals during dis-

charge of the middle portion of the batch.

Sample by repeatedly passing a scoop or pail

through the entire discharge stream. Composite

these samples into one sample for testing pur-

poses. Be sure that the first and last por-

tions of the composite sample are taken as

quickly as possible, but never exceeding 15

min. If it is necessary to transport the sam-

ples away from the mixer to the place where

the slump test is to be performed, combine the

samples and remix them with a shovel to ensure

uniformity.

Testing Procedures

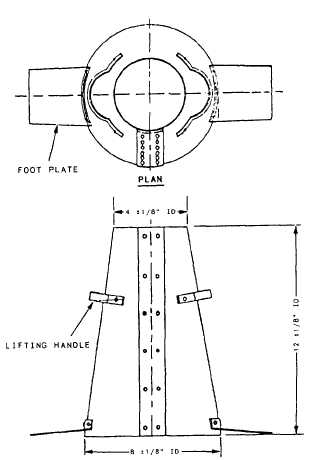

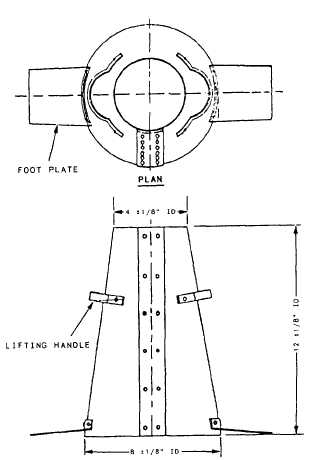

Figure 15-40.-Slump cone.

to the

test load

is applied perpendicular

longitudinal axis of a standard size, premolded,

and-properly cured concrete beam. From this test,

the flexural strength, expressed in terms of

modulus of rupture and given in psi, can be

readily calculated. As with the compression test,

only the procedures to prepare the test beams cor-

rectly will be discussed in this TRAMAN.

SLUMP TESTS

The slump test is performed on newly mixed

concrete. To perform the test, you need a slump

cone and a tamping rod. The slump cone (fig.

15-40) should be made of galvanized steel, 12 in.

in height, with a base opening 8 in. in diameter

and the top opening 4 in. in diameter. Both the

top and bottom openings are perpendicular to the

vertical axis of the cone. The tamping rod is a

straight, steel rod that is 5/8 in. in diameter and

approximately 24 in. in length. One end of the

rod is rounded to a diameter of 5/8 in. (Do not

substitute a piece of rebar.)

Perform the slump test according to ASTM

C 143. Be sure to start the test within 5 min

after obtaining the final portion of the com-

posite sample. In performing the test, first

dampen the slump cone and place it on a flat,

moist, nonabsorbent, rigid surface. From the

composite sample obtained and while standing on

the two foot pieces of the cone, fill the cone in

three layers, each approximately one third of the

volume of the cone. In placing each scoopful of

concrete, rotate the scoop around the top edge

of the cone as the concrete slides from it to

ensure even distribution of concrete within the

mold.

Rod each layer with 25 strokes of the

tamping rod (using the rounded end), and

uniformly distribute the strokes over the en-

tire cross section of each layer. Rod the bottom

layer throughout its depth. Rod the second layer

and the top layer each throughout its depth so

that the strokes just penetrate into the under-

lying layer. In filling and rodding the top

layer, heap the concrete above the mold before

the rodding is started. If the rodding results

15-36