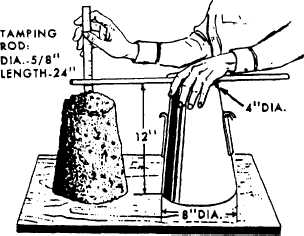

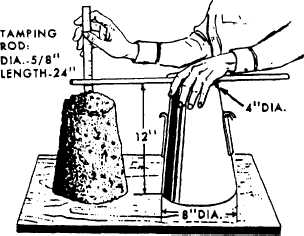

Figure 15-41.-Measurement of slump.

in subsidence of the concrete below the top

edge of the cone, add additional concrete to

keep an excess of concrete above the top of the

cone at all times. After the top layer has been

rodded, strike the surface of the concrete off flush

by means of a screeding and rolling motion of the

tamping rod. Immediately remove the slump cone

from the sample by carefully and steadily lifting

it straight up at the rate of 5 ± 2 sec for the height

of the cone. Place the cone next to the test

specimen. At this point, the entire test from the

start of filling the cone to completing the removal

of the cone should not exceed 2 1/2 min.

In measuring the slump, first place the

tamping rod across the top of the cone so

that it extends over the test specimen as shown

in figure 15-41. Next, measure the vertical

distance from the bottom of the rod to the

average height of the subsided concrete speci-

men. This measurement is known as the SLUMP.

If a decided falling away or shearing off

of concrete from one side or portion of the

specimen mass has occurred, disregard the

slump measurement and make a new test on

another portion of the sample. If two con-

secutive tests show a falling away or shearing

off, the concrete probably lacks the necessary

plasticity and cohesiveness for the slump test to

be applicable.

After measuring and recording the slump, you

have completed the slump test. As a supplemen-

tary procedure, however, tap the sides of the

specimen gently with the tamping rod. The reac-

tion of the concrete indicates its cohesiveness and

workability. A well proportioned, workable mix

gradually slumps to lower elevations and retains

its original identity. A poor mix crumbles,

segregates, and falls apart.

If the slump testis performed for a trial batch

during concrete mix design, then too little, or too

much, slump indicates the need for a new trial

batch with revised ingredient proportions. When

the test is performed as a quality control mea-

sure for a construction project, the slump ob-

tained by testing will be compared to the

specified slump for the concrete used for that

particular project. If too little, or too much,

slump has been determined by the test, then the

quality control inspector, or other appropriate

authority, will determine whether to accept or

reject the concrete.

PREPARATION OF CONCRETE

SPECIMENS

Concrete specimens that are representative of

a distinct batch of concrete must be sampled and

analyzed for the purpose of quality control.

Cylinder Specimens

Tests are performed on concrete cylinder

specimens to evaluate the compressive strength of

the concrete. The standard cylindrical specimen

is 6 in. in diameter by 12 in. long.

STANDARDS FOR CYLINDER MOLDS.—

Cylinder molds should be made of steel, cast

iron, or other nonabsorbent material that does

not react with concrete containing portland

cement or other hydraulic cements. Molds should

hold their dimensions and shapes under conditions

of severe use. They should be able to hold,

without leakage, the water poured into them.

Before using the molds, coat them lightly with

mineral oil or a suitable nonreactive form of

release material.

FILLING CYLINDER MOLDS.— Place the

molds on a level, rigid surface, free of vibration

or other disturbances, at a place as near as possible

to the location where they are to be stored for the

first 24 hr.

Fill the molds with concrete specimens (taken

as previously described for the slump test). The

number of layers is determined by the mold size

15-37