PRESTRESSED CONCRETE

A prestressed concrete unit is one in which

engineered stresses have been placed before it has

been subjected to a load. When PRETENSION-

ING is used, the reinforcement (high-tensile-

strength steel strands) is stretched through the

form between the two end abutments or anchors.

A predetermined amount of stress is applied to

the steel strands. The concrete is then poured,

encasing the reinforcement. As the concrete sets,

it bonds to the pretensioned steel. When it has

reached a specified strength, the tension on the

reinforcement is released. This prestresses the

concrete, putting it under compression, thus

creating a built-in tensile strength.

POST-TENSIONING involves a precast

member that contains normal reinforcing in

addition to a number of channels through which

the prestressing cables or rods maybe passed. The

channels are usually formed by suspending

inflated tubes through the form and casting the

concrete around them. When the concrete has set,

the tubes are deflated and removed. Once the

concrete has reached a specified strength,

prestressing steel strands or TENDONS are pulled

into the channels and secured at one end. They

are then stressed from the opposite end with a

portable hydraulic jack and anchored by one of

several automatic gripping devices.

Post-tensioning may be done where the

member is poured or at the jobsite. Each member

may be tensioned, or two or more members may

be tensioned together after erection. In general,

post-tensioning is used if the unit is over 45 ft long

or over 7 tons in weight. However, some types

of pretensioned roof slabs will be considerably

longer and heavier than this.

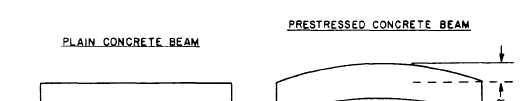

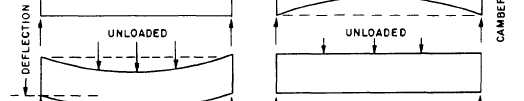

When a beam is prestressed, either by pre-

tensioning or post-tensioning, the tensioned steel

produces a high compression in the lower part of

the beam. This compression creates an upward

bow or camber in the beam (fig. 7-19). When a

load is placed on the beam, the camber is forced

out, creating a level beam with no deflection.

Those members that are relatively small or that

can be readily precast are normally pretensioned.

These include precast roof slabs, T-slabs, floor

slabs, and roof joists.

SPECIAL TYPES OF CONCRETE

Special types of concrete are essentially those

with unique physical properties or those produced

with unusual techniques and/or reproduction

processes. Many special types of concrete are

made with portland cement as a binding medium;

some use binders other than portland cement.

Lightweight Concrete

Conventional concrete weighs approximately

150 lb per cubic foot. Lightweight concrete weighs

20 to 130 lb per cubic foot, depending on its

intended use. Lightweight concrete can be made

by using either gas-generating chemicals or

Figure 7-19.-Comparison of plain and prestressed concrete beams.

7 - 14