beam and girder bars, bends for reinforcement

of vertical columns at or near floor levels,

stirrup and column ties, slab reinforcement, and

bars or wire for column spiral reinforcement.

SPLICES.— Where splices in reinforcing steel

are not dimensioned on the drawings, the bars

should be lapped not less than 30 times the bar

diameter, nor less than 12 in. The stress in a

tension bar can be transmitted through the

concrete and into another adjoining bar by a lap

splice of proper length. The “lap” is expressed

as the number of bar diameters. If using the

No. 2 bar, make the lap at least 12 in.

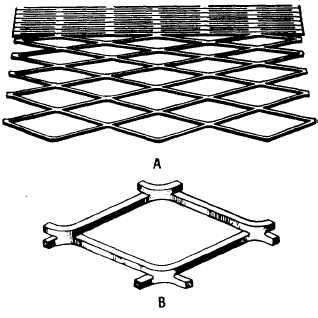

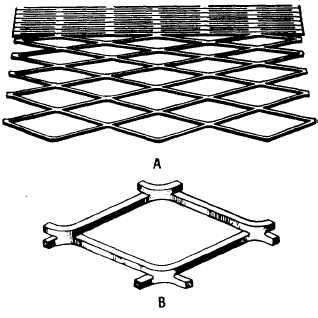

EXPANDED METAL AND WELDED

WIRE FABRIC.— Expanded metal or wire mesh

is also used for reinforcing concrete. Expanded

metal is made by partly shearing a sheet of steel,

as shown in figure 7-13, view A. The sheet steel

has been sheared in parallel lines and then pulled

out or expanded to form a diamond shape

between each parallel cut. Another type is square

rather than diamond shaped, as shown in figure

7-13, view B. Expanded metal is frequently used

during plastering operations.

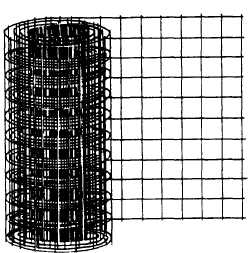

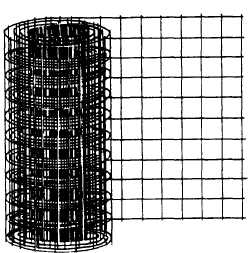

Welded wire fabric is available both in rolls

(fig. 7-14) for light building construction and

sheets for highways and use in buildings when roll

sizes will not give ample reinforcement. Wire

Figure 7-13.-Expanded or diamond mesh steel reinforce-

ment.

Figure 7-14.-Welded wire fabric.

fabric is furnished in both square and rectangular

patterns, welded at each intersection. The rec-

tangular sizes range from 2 by 4 in. to 6 by 12

in. The square patterns are available in 2 by 2 in.,

3 by 3 in., 4 by 4 in., and 6 by 6 in. Both are

furnished in a wide variety of wire gauges. The

square pattern has the same gauge in both

directions, while the rectangular type may have

the same gauge in both directions or the larger

gauge running longitudinally. Specifications and

designs are usually used when wire fabric (mesh)

is being lapped; however, a minimum of 2 in.

between laps is usually sufficient.

Reinforcing bars can be joined together by

different types of ties. Figure 7-15 shows six types

used by the SEABEEs.

PRECAST CONCRETE

Precasting is the fabrication of a structural

member at a place other than its final position

of use. It can be done anywhere, although this

procedure is best adapted to a factory or yard.

Jobsite precasting is not uncommon for large

projects. Precast concrete can be produced in

several different shapes and sizes, including

piles, girders, and roof members. Prestressed

concrete is especially well adapted to precasting

techniques.

Generally, structural members including

standard highway girders, poles, electric poles,

masts,

and building members are precast

by factory methods unless the difficulty or

7-10