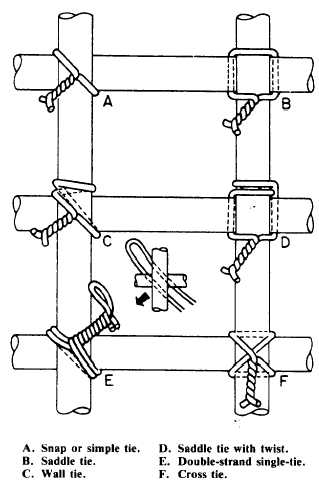

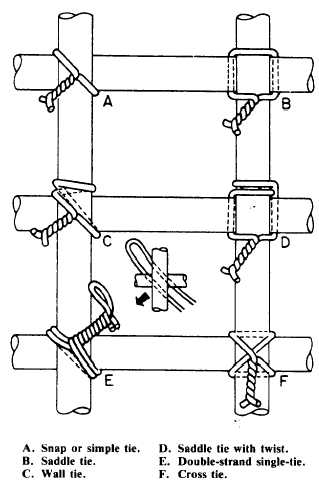

Figure 7-15.-Types of ties.

impracticability of transportation makes jobsite

casting more desirable. On the other hand,

concrete that is cast in the position that it is to

occupy in the finished structure is called cast-in-

place concrete.

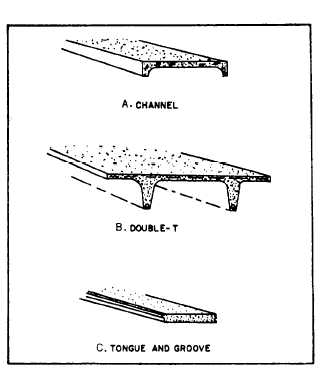

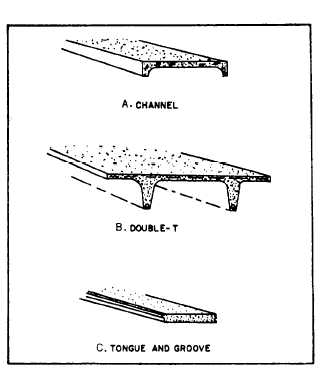

Precast Concrete Floors, Roof Slabs,

Walls, and Partitions

The most commonly used precast slabs or

panels for FLOOR and ROOF DECKS are the

channel and double-T types (fig. 7-16, views A

and B).

The channel slabs vary in size with a depth

ranging from 9 to 12 in., width 2 to 5 ft, and a

thickness of 1 to 2 in. They have been used in

spans up to 50 ft. If desired or needed, the legs

of the channels may be extended across the ends

Figure 7-16.-Typical precast panels.

and, if used in combination with the top slabs.

may be stiffened with occasional cross ribs. Wire

mesh may be used in the top slabs for reinforce-

ment. The longitudinal grooves located along the

top of the channel legs may be grouted to form

keys between adjacent slabs.

The double-T slabs vary in size from 4 to

6 ft in width and 9 to 16 ft in depth. They have

been used in spans as long as 50 ft. When the top-

slab size ranges from 1 1/2 to 2 in. in thickness,

it should be reinforced with wire mesh.

The tongue-and-groove panel (fig. 7-16, view

C) could vary extensively in size, according to the

design requirement. They are placed in position

much like tongue-and-groove lumber; that is, the

tongue of one panel is placed inside the groove

of an adjacent panel. They are often used as

decking panels in large pier construction.

Matching plates are ordinarily welded and

used to connect the supporting members to the

floor and roof slabs.

Panels precast in a horizontal position, in a

casting yard, or on the floor of the building, are

ordinarily used in the makeup of bearing and

nonbearing WALLS and PARTITIONS. These

7-11