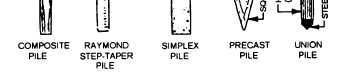

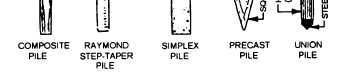

Figure 1-10.—Types of concrete piles.

Bearing Piles

Timber bearing piles are usually straight tree trunks

with the limbs and bark removed. These piles, if kept

continuously wet, will last for centuries; however, they

are used for low design loads because of their

vulnerability to damage while they are being driven into

the ground. The small end of the pile is called the tip;

the larger end is called the butt. Timber piles range from

16 to 90 feet in length with a tip diameter of at least 6

inches. The butt diameter is seldom less than 12 inches.

A steel bearing pile might be an H-pile (having an

H-shaped cross section). These piles are usually used for

driving to bedrock. A steel pile can also be a pipe pile

with a circular cross section. A pipe pile can be either an

open-end pile or a closed-end pile, depending on

whether the bottom end is open or closed.

Concrete piles, such as those shown in figure 1-10,

may be either precast or cast in place. Most precast piles

used today are pretensioned and are manufactured in

established plants. These piles are made in square,

cylindrical, or octagonal shapes. If they are being driven

into soft or mucky soil, they are usually tapered.

Cast-in-place piles are cast on the jobsite and are

classified as shell type or shell-less type. The shell type

is formed by driving a hollow steel tube (shell), with a

closed end, into the ground and filling it with concrete.

The shell-less type is formed by first driving a casing

and core to the required depth. The core is removed and

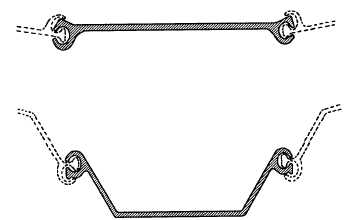

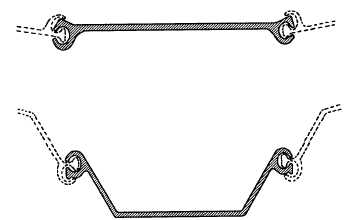

Figure 1-11.—Steel sheetpiling.

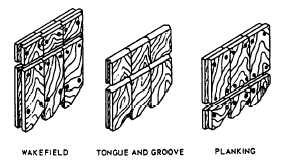

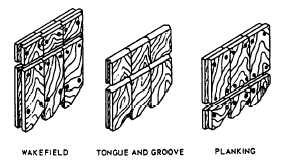

Figure 1-12.—Wood sheet piles.

is then

the casing is filled with concrete. The casing

removed, leaving the concrete in contact with the earth.

Sheet Piles

Sheet piles, made of wood, steel, or concrete, are

equipped or constructed for edge-joining, so they can be

driven edge-to-edge to form a continuous wall or

bulkhead. A few common uses of sheet piles are as

follows:

1. To resist lateral soil pressure as part of a

temporary or permanent structure, such as a retaining

wall

2. To construct cofferdams or structures built to

exclude water from a construction area

3. To prevent slides and cave-ins in trenches or

other excavations

The edges of steel sheetpiling are called interlocks

(fig. 1-11) because they are shaped for locking the piles

together edge-to-edge. The part of the pile between the

interlocks is called the web.

A wood sheet pile might consist of a single, double,

or triple layer of planks, as shown in figure 1-12.

Concrete sheet piles are cast with tongue-and-groove

edges for edge-joining.

1-7