gradation and absence of fines in these sands,

construction equipment may have difficulty in obtaining

traction. Traction can be vastly improved by keeping the

sand wet and by using track-type equipment. These soils

are likely to be “tender” and to require care during final

packing and finishing so that a smooth, dense surface

may be obtained.

3. Silty and clayey soils make satisfactory soil-

cement but those containing high clay contents are

harder to pulverize. Generally the more clayey the soil,

the higher the cement content required to harden it

adequately. Construction with these soils is more

dependent on weather conditions. If the soil can be

pulverized it is not too heavy textured for use in soil-

cement.

SOIL-CEMENT TESTS

Laboratory tests determine three fundamental

control factors for soil-cement. These factors are as

follows:

1. Proper cement content

2. Proper moisture content

3. Roper density

An adequate cement content is the first requisite for

quality soil-cement. Well before construction, the soils

at a project site should be identified, the limits of each

soil defined, and a representative sample of each soil

type should be forwarded to the laboratory to determine

the quantity of cement required to harden it. A soil

survey of the construction area should be made.

Proper soil surveying, identification, and sampling

are important. For instance, if one soil type was sampled

and tested while actual construction involved a different

soil type, the tests would be worthless and, in fact,

detrimental since they would mislead the engineers.

Obviously, it is important to sample and test the soils

that will actually be used in soil-cement construction. A

75-pound sample of each type of soil is adequate for

laboratory testing.

Sampling methods and procedures are discussed in

the EA3 TRAMAN and in NAVFAC MO-330. Soil

samples are usually taken from a graded roadway by

digging a trench from the center line to the edge of the

proposed pavement and to the depth of processing. Soil

samples for proposed roadways not yet graded are taken

with an auger from the various soil horizons of each soil

type from the “dressed-down” face of exposed cuts or

from the surface. Samples should be taken so that only

one horizon of each soil type is represented by each

sample. Similarly, it is not good practice to take a

composite sample from various locations. Data obtained

from a composite sample does not apply to soil in any

single location and may be misleading. There are

exceptions. For instance, in sampling pit material that is

to be loaded during construction by a shovel operating

over the vertical face of the pit, the sample is taken from

the bottom to the top of the vertical face after the

overburden is removed. On small projects, it is not

uncommon to sample only the poorest soil on the job,

and the cement content for this sample is used

throughout the job. Be sure that complete identification

is supplied with each sample.

The purpose of laboratory testing is to determine the

minimum cement content needed to harden the material

adequately and the optimum moisture content (OMC)

and density values to be used for construction. The

OMC and maximum density are determined by the

moisture-density test and the required cement content

is determined by either the wet-dry test for pavements

located in nonfrost areas or the freeze-thaw test for

pavements located in frost areas. A brief description of

each test is provided below.

. The moisture-density test determines the OMC

and maximum density for molding laboratory

specimens and, in the field, to determine the quantity of

water to be added and the density to which the

soil-cement mixture should be compacted.

Before you start this test, select the cement contents

that will be used in the wet-dry or freeze-thaw test. The

cement contents are usually selected in 2-percent

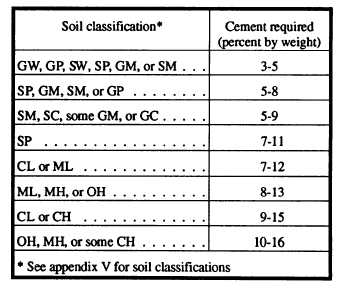

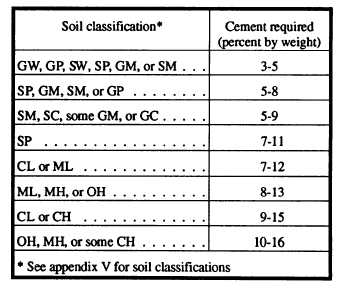

increments to encompass values given in table 18-3.

Table 18-3.—Basic Range of Cement Requirements

18-6