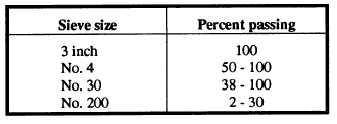

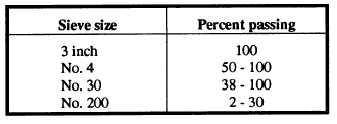

Table 18-4.—Recommended Gradations for Bituminous-

Stabilized Subgrade Materials

tables 18-4 and 18-5, respectively. Mechanical

stabilization may be required to bring the soil to proper

gradation.

TYPES OF BITUMEN

Bituminous stabilization is generally accomplished

using asphalt cement, cutback asphalt, or asphalt

emulsion. The type of bitumen to be used depends upon

the type of soil to be stabilized, method of construction,

and weather conditions.

In frost areas, the use of tar as a binder should be

avoided because of its high-temperature susceptibility.

Asphalts are affected less by temperature changes, but

a grade of asphalt suitable to the prevailing climate

should be selected. As a general rule, the most

satisfactory results are obtained using the most viscous

liquid asphalt that can be readily mixed into the soil. For

higher quality mixes in which a central plant is used,

viscosity-grade asphalt cements should be used.

Most bituminous stabilization is performed in place.

The bitumen is applied directly on the soil or

soil-aggregate system, and the mixing and compaction

operations are conducted immediately thereafter. For

this type of construction, liquid asphalts, such as cut-

backs and emulsions, are used. Emulsions are preferred

over cutbacks because of energy constraints and

pollution control efforts.

The specific type and grade of bitumen will depend

on the characteristics of the aggregate, type of con-

struction equipment, and climate conditions. Generally,

the types of bituminous materials that will be used for

the soil gradation are indicated in table 18-6.

MIX DESIGN AND METHODS

OF TESTING MIXTURES

For guidance on the design of bituminous-stabilized

base and subbase courses, you should refer to

Bituminous Pavements—Standard Practice, TM5-

822-8, and to NAVFAC MO-330.

The Tentative Method of Testing Soil-Bituminous

Mixtures, ASTM D 915, provides for determination of

water absorption, expansion, and extrusion

characteristics of compacted soil or soil-aggregate

mixtures. The method maybe used for determining the

characteristics of a mixture of specified proportions

under specified conditions of curing or noncuring. Also,

it may be used for determining the effects on these

characteristics of varying the curing and the proportions

of the different ingredients. The test results are not

intended to determine thickness or to predict relative

field performance of the different bituminous materials.

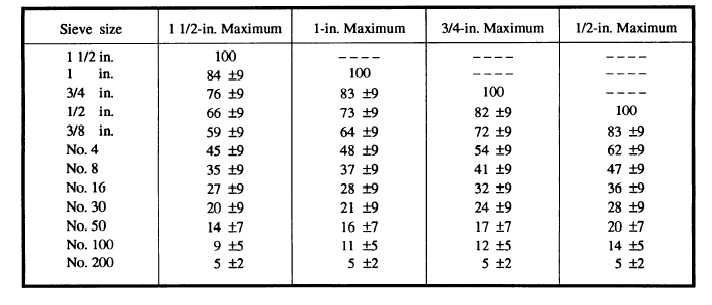

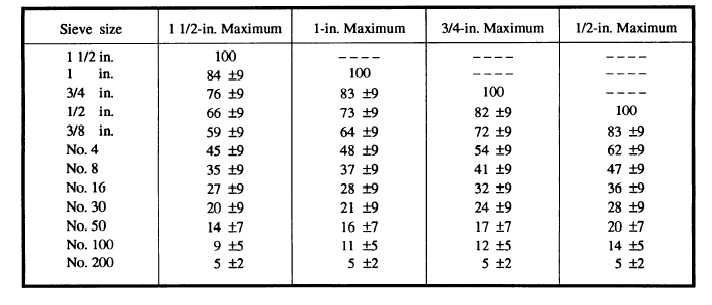

Table 18-5.—Recommended Gradations for Bituminous-Stabilized Subbase Materials

18-8