defined in terms of measurable parameters such as

enough improvement to offset the cost. When that

failure rate, time to repair, material condition index

happens, the SYSCOM or PM should recommend to

(MCI), costs, and support delay time. (The MCI is a

CNM via the DPD that the equipment be deleted from

computerized index that considers the number and

the DART program. This kind of recommendation must

severity of casualties reported within a given period of

include justification.

time, and averages the time needed to correct the

The scoping phase must include a realistic course of

casualty.) Use all available sources of information to

define the problem. If fleet data is not adequate, call in

action that includes resources in finds and manpower to

observers who are technically qualified rather than

implement the improvement program. Most solutions

impose special data collection systems on the fleet. The

will be a combination of changes in design and

hardware, personnel allowances and training, technical

priority of the DART program justifies these actions to

save time and provide complete, factual, and

publications, maintenance or operating policies and

comprehensive data.

procedures, and funding.

Sometimes, the scoping phase will show that you

The SYSCOM or PM will submit a description of

need more resources than you can justify to fix a

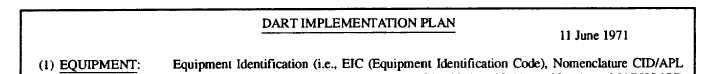

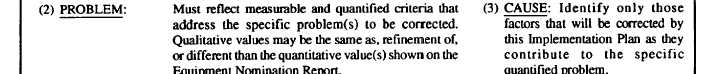

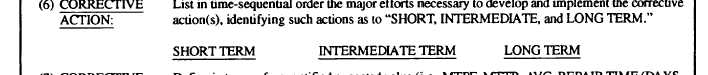

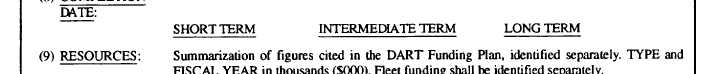

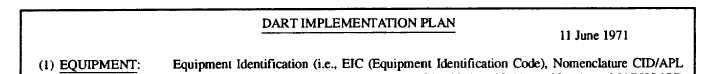

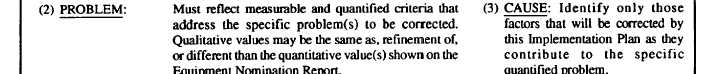

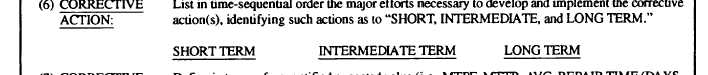

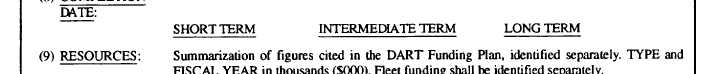

the improvement program to the DPD in the following

particular kind of equipment problem. As an example,

three plans:

the most common situation occurs when there is not

1. An implementation plan (see fig. 7-3)

Figure 7-3.-DART implementation plan.

7-9