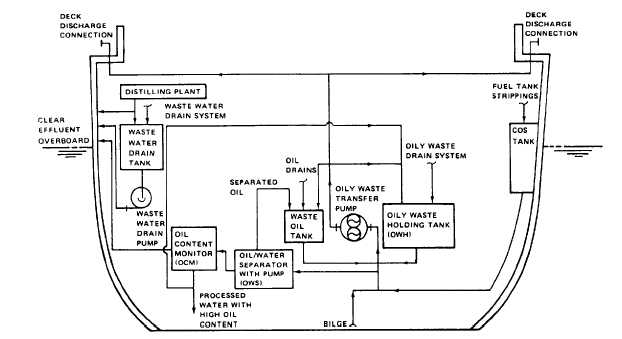

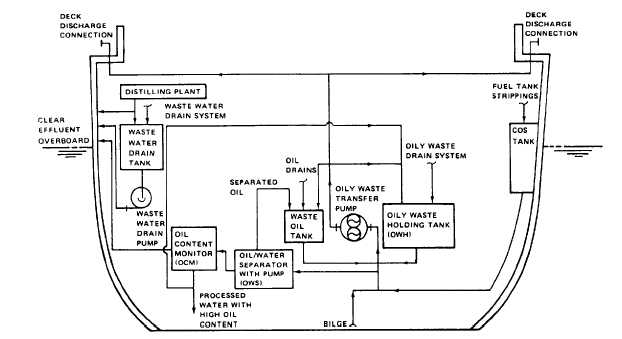

Figure 6-1.-Typical shipboard oil pollution control system.

following lists show common sources of oil and oily

waste that find their way into the water.

1. Lubricating oil

a. Leakage and drainage from equipment and

systems

b. Contaminated oil from centrifugal purifiers

c. Used oil removed from equipment during an

oil change

2. Fuel oil

a. Spillage during fueling, defueling, and

internal transfer operations

b. Leakage through hull structures into bilges

c. Stripping from the contaminated oil settling

tank

d. Ballast water from fuel tanks of

noncompensated fuel systems or bulk carriers

e. Ballast water from compensated fuel tank

systems during refueling, defueling, and internal

transfer operations

f. Tank cleaning operations

3. Hydraulic fluids

a. Leakage of hydraulic fluid from glands and

seals into hydraulic pump room bilges

b. Spillage during system filling or

replenishment

c. Spillage caused by hydraulic system

casualties

HANDLING OIL SPILLS

All oil spills and slicks or sheens within the 50-mile

prohibited zone of the United States shall be reported

immediately according to the Environmental and

Natural Resources Program Manual, OPNAVINST

5090.1. Navy ships can now provide immediate

remedial action on oil spills until they are relieved by

shore-based response units. Since U.S. shorebased units

are seldom available in non-Navy or foreign ports, a

ship may have to clean up the entire spill.

A cleanup kit has been developed for use by the

ship’s crew. The U.S. Navy Oil Spill Containment and

Cleanup Kit, NAVSEA 0994-LP-013-6010, contains a

description of the kit and instructions for its use. The

manual describes safety precautions for use of the kit as

well as the recommended shipboard allowance. A

trained crew that acts quickly can contain a spill, and it

can often collect the entire spill without help from

shore-based personnel.

6-3