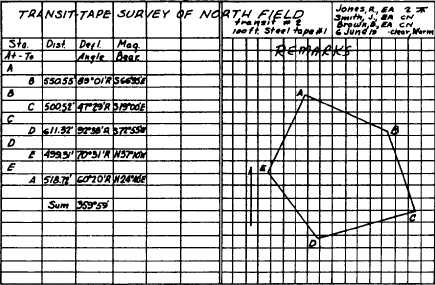

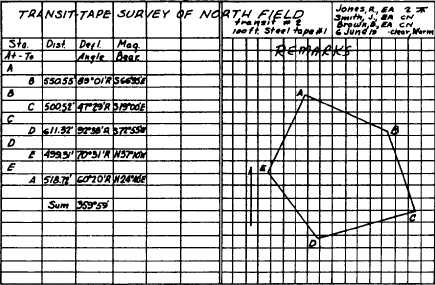

Figure 13-12.-Sample field notes from a deflection angle transit-tape survey.

2. Read the vernier with the eye directly over

the top of the coinciding graduations to eliminate

the effects of parallax.

3. Take the reading of the other vernier as a

check. The readings should be 180° apart.

4. Check the plate bubbles before measuring

an angle to see if they are centered, but do not

disturb the leveling screws between the initial and

final settings of the line of sight. If an angle is

measured again, the plate may be releveled after

each reading before sighting again on the starting

point.

5. Make sure that the rodman is holding the

range pole truly vertical when you sight at it.

When the bottom of the range pole is not visible,

let the rodman use a plumb bob.

6. Avoid accidental movement of the horizon-

tal circle; for instance, moving the wrong clamp

or tangent screw. If a number of angles will be

observed from one setup without moving the

horizontal circle, you should sight at some clearly

defined distant object that will serve as a reference

mark and take note of the angle. Occasionally,

you should recheck the reading to this point

during measurement to see if there is any

accidental movement.

An example of a horizontal deflection angle

measurement is shown in figure 13-12. The field

notes contain data taken from a loop traverse

shown in the sketch. The transit was first set up

at station A, and the magnetic bearing of AB was

read on the compass. Then the deflection angle

between the extension of EA and AB was turned

in the following manner:

1. The instrumentman released both clamps,

matched the vernier to zero by hand, tightened

the upper motion clamp, and set the zero exactly

with the upper tangent screw.

2. With the telescope plunged (inverted

position), the instrumentman sighted the range

pole held on station E. Then he tightened the

lower motion clamp and manipulated the lower

motion tangent screw to bring the vertical cross

hair to exact alignment with the range pole.

3. The instrumentman replunged the telescope

and trained on the extension of EA. (Notice that

the telescope is in its normal position now.) He

then released the upper motion and rotated the

telescope to the right until the vertical cross hair

came into line with the range pole held on

station B. He further set the upper motion clamp

screw and brought the vertical cross hair into

exact alignment with the range pole by manipu-

lating the upper motion tangent screw.

4. The instrumentman then read the size of

the deflection angle on the A vernier (89°01´).

Since the angle was turned to the right, he

recorded 89°01´R in the column headed “Defl.

Angle.”

Likewise, he recorded the chained

distance between stations A and B and the

magnetic bearing of traverse line AB under their

appropriate headings.

13-11