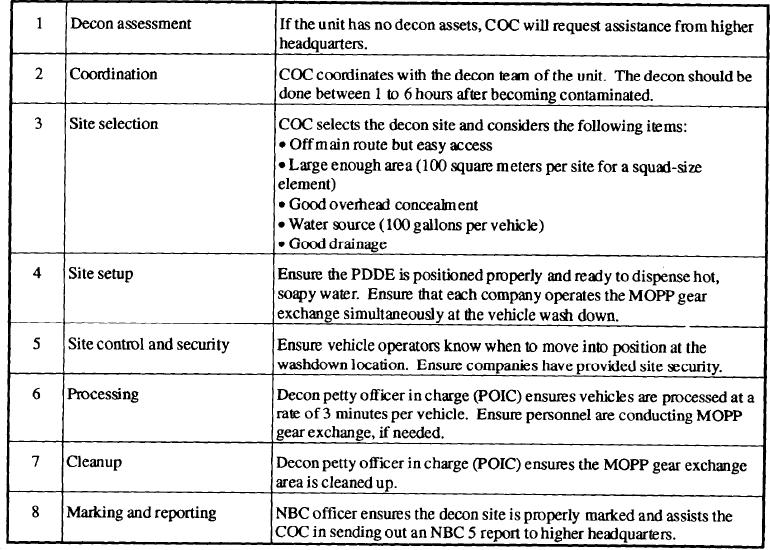

Table 6-4.--Operational Decon Checklist.

and is the most resource intensive. Weathering causes

It is important to remember that performing

operator's spray down before hasty decon will

a significant reduction of contamination overtime, but

decrease the contamination transfer and increase the

the immediate reduction of contamination to

survivability of the crew.

negligible risk levels does not normally occur.

Weather conditions, agent used, mission

THOROUGH DECON OPERATIONS

requirements, time, troops, and supplies available may

all combine to make weathering the decon option of

Thorough decon operations reduce contamination

choice. Based on the recommendation of the CBR

to negligible risk levels. They restore combat power

officer, the COC decides which type of decon is the

by removing nearly all contamination from unit and

most efficient and effective for their unit.

individual equipment. Thorough decon enables

troops to operate equipment safely for extended

A limiting factor that must be considered when

periods at reduced MOPP levels. A small risk

planning any decontamination operations is the

remains, so periodic checks with the CAM, M8/M9

availability of water. A typical vehicle will require

paper, or M256-series kit must be made after each

500 gallons of water during detailed equipment decon.

operation. After thorough decon, the unit moves out

of the decon site into a tactical assembly area. The

In a water-scarce environment, such as deserts, the

unit, while in this tactical assembly, may undergo

CBR officer must cordinate a water resupply plan

reconstitution or prepare for future operations.

with other units in the area of operation. A water

resupply plan can include selecting a series of link-up

Operational decon requires fewer resources but

points along a route. The unit can link up with a bulk

physically removes only surface contamination.

water truck from other units. More complex water

Thorough decon is the most effective type of decon