is better than a plain round or square one. In fact, when

plain bars of a given diameter are used instead of

deformed bars, approximately 40 percent more plain

bars must be used.

The adherence of the concrete depends on the

roughness of the steel surface: the rougher the steel, the

better the adherence. Thus, steel with alight, firm layer

of rust is superior to clean steel, but steel with loose or

scaly rust is inferior.

Loose or scaly rust may be

removed from the steel by rubbing the steel with burlap.

The requirements for reinforcing steel are that it be

strong in tension and, at the same time, ductile enough

to be shaped or bent cold.

Reinforcing steel may be used in the form of bars

or rods that are either PLAIN or DEFORMED or in the

form of expanded metal, wire, wire fabric, or sheet

metal. Each type is useful for a different purpose, and

engineers design structures with these purposes in

mind.

Plain reinforcing bars are usually round in cross

section. They are used as main tension reinforcement

for concrete structures. They are the least used of the

rod type of reinforcement because they offer only

smooth, even surfaces for the adherence of concrete.

Reinforcing bars or rods are commonly referred to as

rebars.

Deformed bars are like the plain bars except that

they have either indentations in them or ridges on them,

or both, in a regular pattern. The twisted bar, for

example, is made by twisting a plain square bar cold.

The spiral ridges along the surface of the deformed bar

increase its bond strength with concrete. Other forms

used are the round- and square-corrugate d bars. These

bars are formed with projections around the surface that

extend into the surrounding concrete and prevent

slippage. Another type is formed with longitudinal fins

projecting from the surface to prevent twisting. Figure

7-10 shows a few of the various types of deformed bars

available. In the United States, deformed bars are used

almost exclusively, while in Europe, both deformed and

plain bars are used.

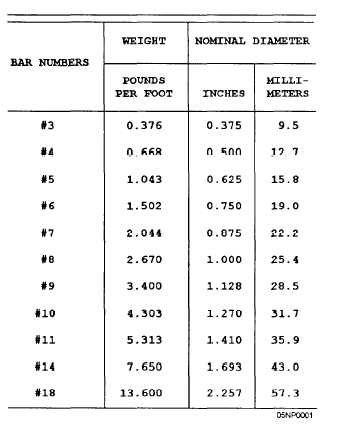

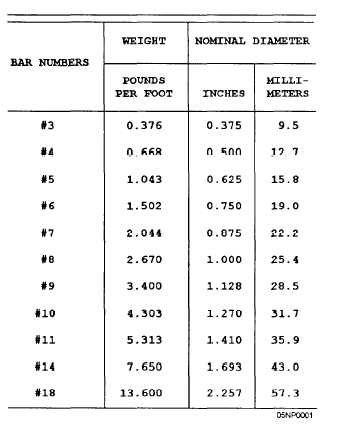

There are 11 standard sizes of reinforcing bars.

Table 7-1 lists the bar numbers, weight, and nominal

diameters of the 11 standard sizes. Bars No. 3 through

No. 18, inclusive, are deformed bars. Remember that

bar numbers are based on the nearest number of 1/8 in.

(3. 175 mm) included in the nominal diameter of the bar.

To measure rebar, you must measure across the

roundsquare portion where there is no deformation.

Table 7-1.-Standard Reinforcing Bars

The raised portion of the deformation is not considered

in measuring the rebar diameter.

BENDS.— Frequently, it is required that

reinforcing bars be bent into various shapes. There are

several reasons for this. First, let us go back to the

reason for using reinforcing steel in concrete—to

increase the tensile and compressive strength of

concrete. You might compare the hidden action within

abeam from live and dead loads to breaking a stick over

your knee. You have seen how the splinters next to your

knee push toward the middle of the stick when you

apply force, while the splinters from the middle to the

opposite side pull away from the middle. This is similar

to what happens inside the beam.

For instance, take a simple beam (a beam

resting freely on two supports near its ends). The

dead load (weight of the beam) causes the beam to

bend or sag. Now, from the center of the beam to

the bottom, the forces tend to stretch or

7-7