lengthen the bottom portion of the beam. This

part is said to be in tension, and that is where the

steel reinforcing bars are needed. As a result of

the combination of the concrete and steel, the

tensile strength in the beam resists the force of

the load and keeps the beam from breaking apart.

At the exact center of the beam, between the

compressive stress and the tensile stress, there is

no stress at all—it is neutral.

In the case of a continuous beam, it is a little

different. The top of the beam may be in

compression along part of its length and in

tension along another part. This is because a

continuous beam rests on more than two supports.

Thus, the bending of the beam is NOT all in one

direction but is reversed as it goes over

intermediate supports.

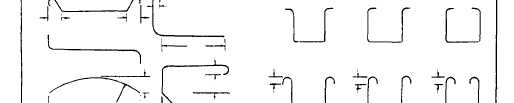

To help the concrete resist these stresses,

engineers design the bends of reinforcing steel so

that the steel will set into the concrete just where

the tensile stresses take place. That is why some

reinforcing rods are bent in almost a zigzag

pattern. The joining of each bar with the next,

the anchoring of the bar ends with concrete, and

the anchoring by overlapping two bar ends

together are some of the important ways to

increase and keep bond strength. Some of the

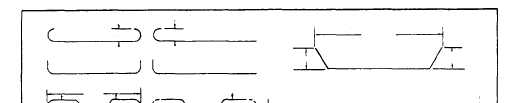

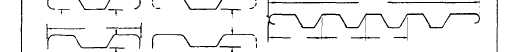

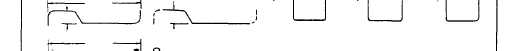

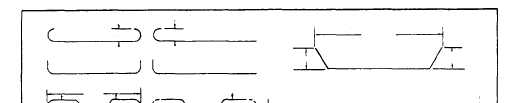

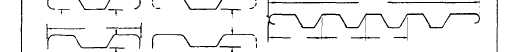

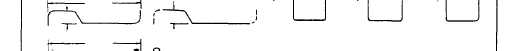

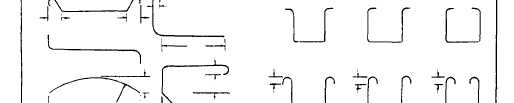

bends you will encounter are shown in figure 7-11.

Figure 7-11.-Typical reinforcement bar bends.

7-8