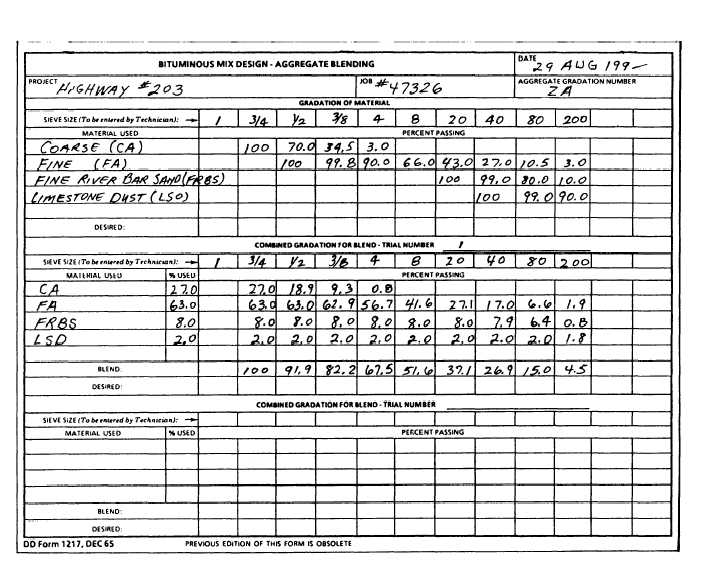

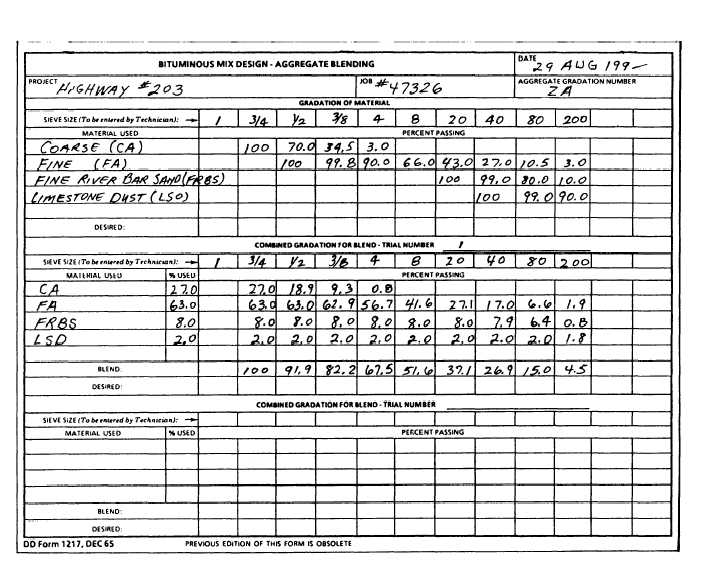

Figure 13-36.-Data sheet for aggregate gradation of trial blends (DD Form 1217).

primary roads. Seventy-five blows produce the

equivalent of a tire pressure of 200 psi; 50 blows

produce the equivalent of a tire pressure of 100 psi. After

the compaction process, place the mold in a

bearing-ratio jack and extract the compacted sample

with extraction equipment.

Density and Voids Determination

Density of the specimens should be determined by

weighing in air and in water. A direct weight in water of

open-textured or porous specimens will give erroneous

results because of absorption of water, and other means

must be used to determine the volume of the specimen.

One means of measuring the volume of a porous

specimen is to coat the specimen with paraffin to seal

.

all the voids and then weigh the coated specimen in air

and in water. A correction is made for the weight and

volume of the paraffin. The difference between these

two weights, in grams, gives the volume of the specimen

in cubic centimeters. You can then determine the unit

weight (density) of the mix in pounds per cubic foot for

each specimen by multiplying the specific gravity of the

specimen by 62.4 pounds (weight of 1 cubic foot of

water). Before carrying out the calculations for percent

of voids, you must know the specific gravity of the

aggregate blend and the asphalt content used.

Stability and Flow Determination

A full discussion of the method used to test for

stability and flow can be found in NAVFAC MO-330;

13-49