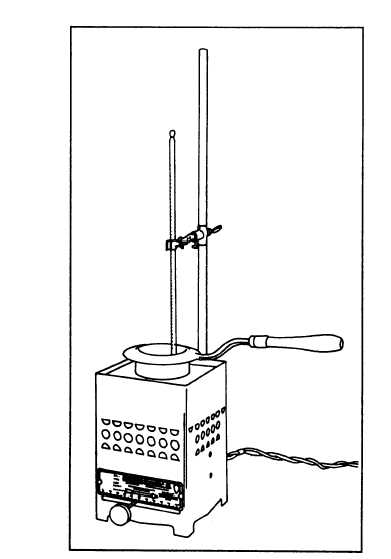

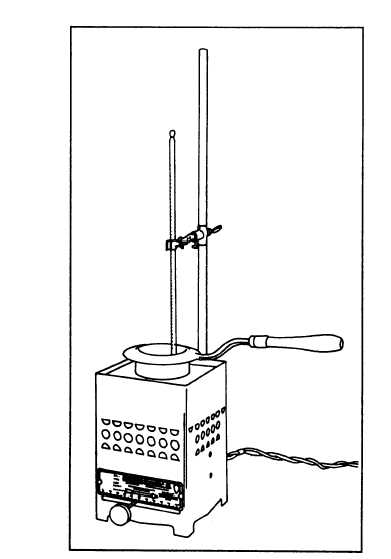

Figure 13-32.-Cleveland open-cup flash point tester.

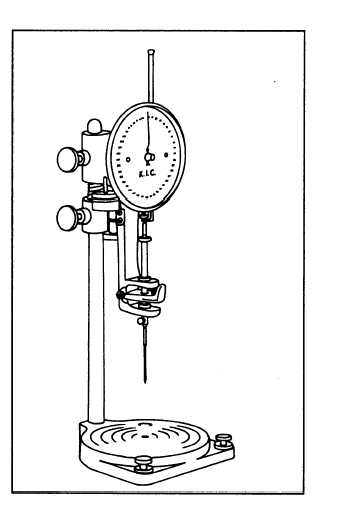

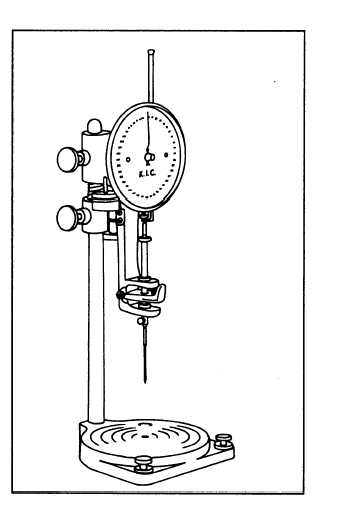

In addition to grade determination, the penetration

test is useful for other purposes, such as detecting

overheating or prolonged heating of asphalts in storage

tanks. Also, when the asphalt is extracted from a

pavement, the penetration test is useful in determining

how the asphalt has changed with age and weathering.

TESTS ON AGGREGATE

The desired characteristics of aggregates used for

bituminous paving include angular shape, rough

surface, hardness, and gradation. These qualities and

grain distribution largely affect the quality of the

resulting pavement. The larger, coarse aggregate

particles are the main structural members of the

pavement; however, if there were nothing but large

particles, there would be many unfilled voids between

adjacent particles. The fewer voids the mixture has, the

more dense the pavement and, therefore, the more

Figure 13-33.-Asphalt penetrometer.

durable it is. Ideal density is obtained by filling the voids

between the largest particles with smaller particles, and

soon, right down through the whole range of sizes from

coarsest to finest.

Common practice divides the aggregates used for

bituminous paving into coarse aggregate (retained on

the No. 10 sieve), fine aggregate (retained on the No.

200 sieve), and mineral filler. Usually 65 percent or

more of the mineral filler will pass the No. 200 sieve.

The distribution of the sizes determines how many voids

will remain and aids in determining how much bitumen

will be needed.

The EA must be able to perform a number of tests

on aggregates to determine their acceptability y for

bituminous construction. One test is the grain size

distribution test that is done by sieve analysis, using the

same procedure as described for soil in the EA3

TRAMAN. Tests for mineral dust and specific gravity

are also needed. Instructions for conducting both these

tests are contained in the following paragraphs.

13-45