that has a thermometer running through the stopper, as

shown. The flask and contents are heated. As the

temperature rises, distillate is given off in the form of

vapor. A condenser returns the vapor to liquid form, and

the liquid (the distillate) is caught in a volumetric beaker.

The test indicates what can be expected in the

application and use of the materials. The distillation

temperature ranges from 374°F to 680°F for RC asphalt

cutbacks, from 437°F to 680°F for MC, and only at

680°F for SC. Road tars are distilled at temperatures that

range from 338°F to 572°F, and tar-rubber blends from

170°F to 355°F. The amount distilled is expressed as a

percentage of the total. The residue is the difference

between the distillate and the total. The percentages of

distillation may be as little as 1 percent for tar-rubber

distilled at 170°C (338°F) to as much as 59 percent when

RC and MC cutbacks and tars are heated to the higher

temperatures.

Record the volume of bitumen remaining in the

flask. If the residue is solid enough to be tested, it is

subjected to the penetration test described later in this

chapter. If it is solid enough for this test, the residue must

be asphaltic cement, and the original material was either

RC or MC. If it is not solid enough for penetration

testing, the original material was SC.

Finally, you can determine the grade by calculating

the percentage of bitumen and comparing it with the

ranges previously given.

Flash Point Tests

The flash point of a bitumen that contains a volatile

distillate is the temperature at which it begins to give off

ignitable vapor. The principal purpose of flash-point

testing is to determine maximum safe mixing and

applying temperatures; however, these tests are an aid

to identification as well. Referring again to table 13-6,

you see that RC and MC have flash points below 175°F.

MC-30 and SC-70 have flash points around 150°F, but

the other grades of SC have flash points above 175°F.

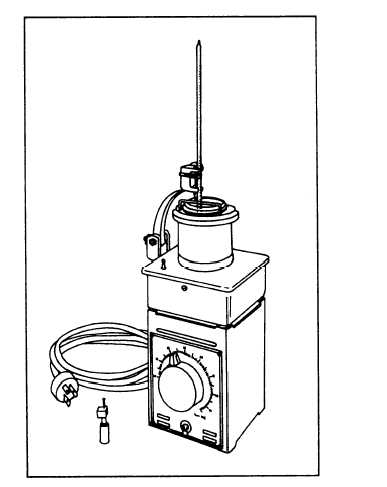

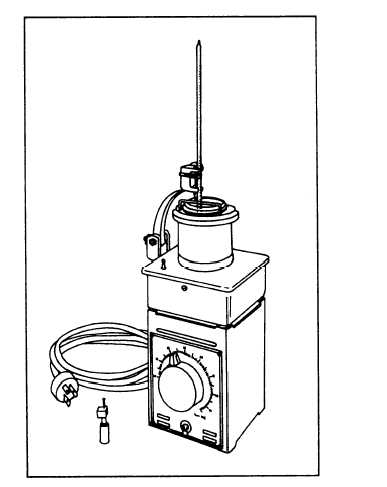

Testing for a flash point below 175°F is done with

the tag open-cup equipment shown in figure 13-31.

When testing for flash points above 175°F, use the

Cleveland open-cup equipment shown in figure 13-32.

When using either of these testers, you need to follow

the procedures described in NAVFAC MO-330. While

there are important procedural differences, flash-point

testing using either equipment is similar in that you use

the equipment to heat the test sample at a prescribed rate

of temperature increase. Then, when the temperature

reading on the thermometer nears the estimated flash

Figure 13-31.—Tag open-cup flash point tester.

point (table 13-6), you use an alcohol torch to begin

passing a flame across the surface of the sample. The

flash point is reached when the test flame produces a

distinct flicker or flash on the surface of the sample. At

this point you read the thermometer and record the

temperature.

Penetration Test

Figure 13-33 shows an asphalt penetrometer that is

used to determine the grade of asphalt cement. In

performing the test, the needle is carefully brought to

contact with the surface of the sample, then released so

as to exert a pressure of 100 grams. The seconds after

the needle is released, the distance it penetrated the

sample is read, to the nearest 0.01 centimeter, on the

penetrometer dial. The reported penetration is the

average of at least three tests on the same material whose

values do not differ more than four points between

maximum and minimum. Detailed procedures can be

found in NAVFAC MO-330.

13-44