Figure 13-34.-Dunagan apparatus for specific gravity test.

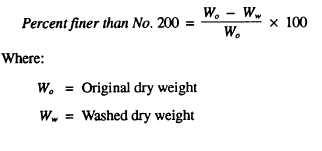

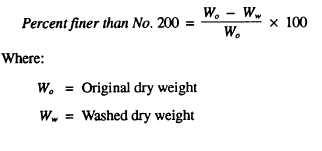

Test for Mineral Dust

In bituminous paving, particles finer than the No.

200 sieve are referred to a mineral dust. To measure the

amount of mineral dust in a selected sample, you

perform a washed sieve analysis (discussed in the EA3

TRAMAN), using the No. 40 and No. 200 sieves. After

all the material possible has passed the No. 200 sieve

and has been discarded, the materials remaining on the

sieve are returned to the original washed sample,

oven-dried, and weighed The amount of mineral dust is

then calculated, using the following formula:

Tests for Specific Gravity

The specific gravities of aggregates used in

bituminous paving mixtures are required in the

computation of the percent of air voids and percent of

voids filled with bitumens. Apparent specific gravity

used with aggregate blends showing water absorption

of less than 2 1/2 percent is based upon the apparent

volume of the material, which does not include those

pore spaces in the aggregate that are permeable to water.

Bulk-impregnated specific gravity is used for aggregate

blends with 2 1/2 percent or greater water absorption

The methods for determining absorption were discussed

earlier in this chapter in the discussion of concrete

aggregates.

The apparent specific gravity can be determined

using the methods described in NAVFAC MO-330 for

apparent and bulk specific gravity. It may also be

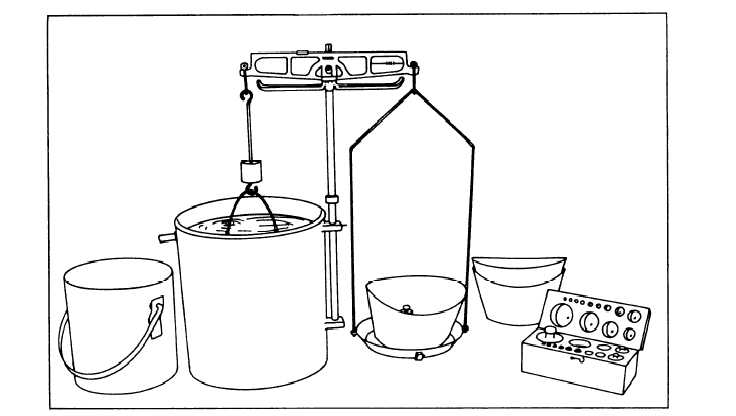

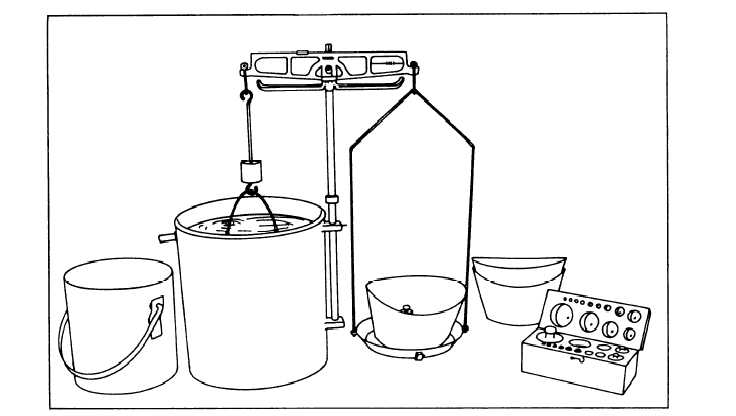

determined using the Dunagan apparatus shown in

figure 13-34. The procedures are as follows:

1. Select approximately 5,000 grams of aggregate

from the sample, not including particles smaller than the

3/8-inch sieve.

2. Wash the aggregate to remove any dust or other

coating and dry it to constant weight in the oven. Record

the total weight of ovendry aggregate on the data sheet,

as shown in figure 13-35.

3. Immerse the aggregate in water at 15°C to 25°C

for a period of 24 hours.

13-46