reaches the shipyard, and they hold a pre-arrival conference

with the ship’s officers and the TYCOM’s representative.

When the results of a pre-arrival inspection, or other

firm information, are available, the planning department

prepares job orders based on ship work requests. It also

prepares a list of the materials needed to do the job or a

budget figure if no list is available. Then they send the

job order and material list to the production department

where the repair division adds key operation dates and

material required dates (MRD).

Sometimes there is a need for work that could not

be foreseen and the planning department issues work

request supplements to cover those situations. These

supplements are restricted and should be used only

when necessary.

The planning department prepares allowance lists,

such as the COSAL, for newly constructed ships, and

corrects existing allowance lists for ships for which the

shipyard is the home yard. These are lists of equipment

components, repair parts, or material needed to operate,

maintain, and repair the ship for specified periods of

time. They are based on plans, material requisitions, or

individual job orders related to the ship’s equipment.

The planning department’s design division issues

procedures to carry out tests of equipment and work.

(The combat systems office and nuclear engineering

department conduct their own tests.) The procedures

include any special measures and safety precautions and

an outline of the reports to be made on the test results.

Each ship undergoing overhaul assigns inspectors and

representatives from each department to inspect work

and witness tests, since these are a responsibility of the

commanding officer as outlined in U. S. Navy

Regulations.

PRODUCTION DEPARTMENT (SHOPS)

The production department is made up of all of the

shops in a naval shipyard and is supervised by the

production officer. Each shop is a unit that is assigned

specific work, usually by trade. Most shops are assigned

to the production department, but they usually do work

for the entire yard. (The transportation, power plant, and

maintenance shops are assigned to the public works

department.) Figure 9-4 shows the organization of a

typical production department.

Each shop in the production department is assigned

to a shop group consisting of one or more shops. Each

shop group has a civilian superintendent who is

responsible for the organization, administration,

personnel training, and general supervision of his shop

group. A civilian superintendent is in charge of each

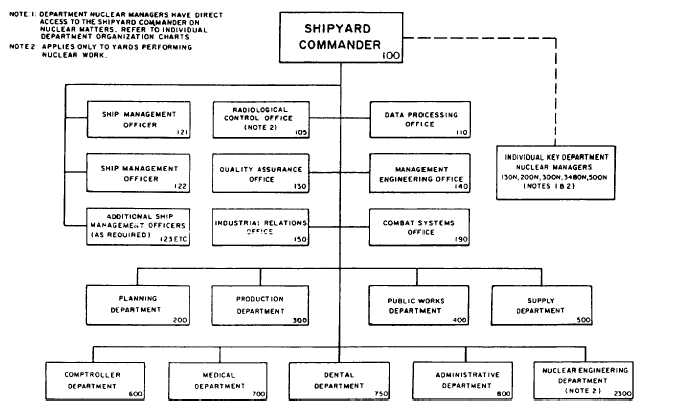

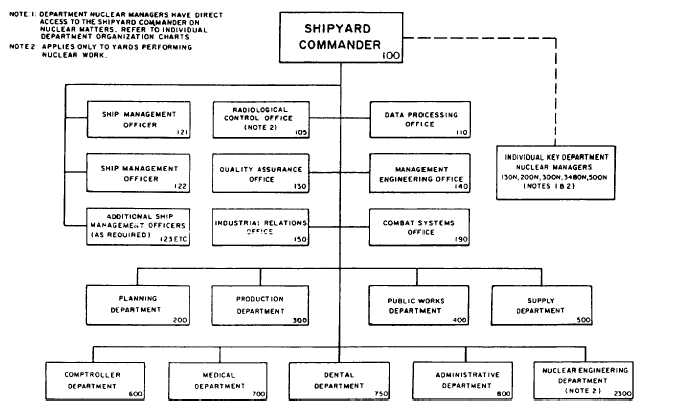

Figure 9-2.-Organization of a typical naval shipyard.

9-9