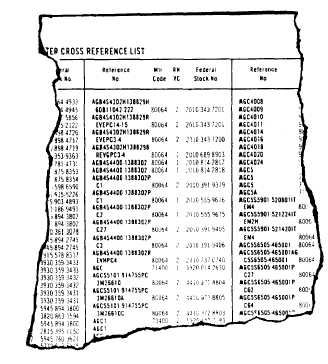

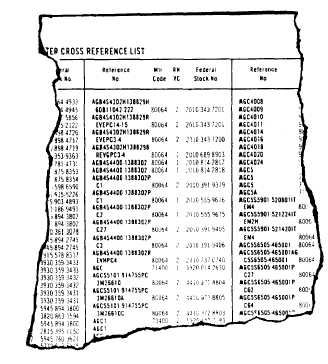

Figure 5-7.-Format for the master cross-reference list

(MCRL).

An ILO is the work that is done during a supply

availability and it begins concurrently with the shipyard

overhaul. Storekeepers off-load repair parts, and they

identify, inspect, inventory, repackage, and preserve

them as needed. They will get any help they need from

other departments, and the engineering department will

probably be asked to provide one or more experienced

petty officers for this purpose. A good ILO purifies the

selection of repair parts carried in supply department

storerooms.

If the validation does not find equipment it should

find, it will delete those items from the ship’s

configuration, which means deletion from the COSAL

and other support documents. Therefore, engineering

department personnel should be sure the ILO team can

locate all equipment (or document its location) that

should remain in the ship’s configuration, and they

should certify all deleted equipment that will not be

replaced.

REPAIR PARTS PROCEDURES AND

PROCUREMENT

The supply department is expected to keep enough

repair parts and consumables to meet the demands of the

ship, and that requires cooperation from other

departments. Today’s Navy requires more

for material received and consumed,

accounting

and those

procedures are more complicated than they were a few

years ago. The following paragraphs cover the

procedures commonly used to account for repair parts.

We’ll discuss controlled equipage procedures later in

this chapter.

ISSUES FROM SUPPLY DEPARTMENT

STOREROOMS

NAVSUP form 1250 is used on all nonautomated

ships for issues from supply department storerooms

(ships not using electronic data processing equipment to

request material and record material consumption).

Automated ships use the DD form 1348 as an internal

issue document.

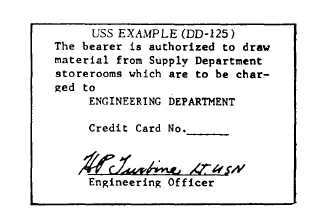

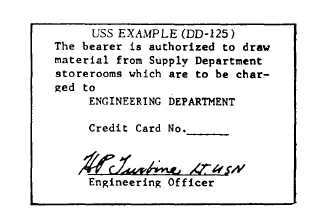

The head of a department must authorize persons to

draw routine issues of repair parts and consumables

from supply. The authorization may be in a memo to the

supply officer that names persons authorized to draw

material. It may also be a locally developed “credit card”

similar to the one shown in figure 5-8 and controlled by

the head of a department. It is best to limit the number

of persons authorized to draw material to keep better

control of the department budget.

SPECIAL REQUIREMENTS

Most material carried on board is repair parts

authorized by the COSAL or consumables stocked on

the basis of past usage. Any others are special

requirements and they include greater numbers of

current items, or items not carried. Submit special

requirements to the supply officer well ahead of the time

you will need them.

Figure 5-8. –"Credit card" authorization to draw stores from

supply department storeroom.

5-15